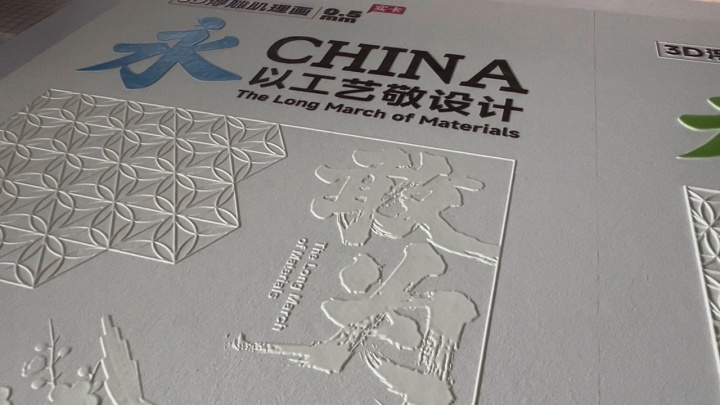

With the rapid development of UV technology, YDM has gained worldwide popularity and trust from customers thanks to its independently developed 3D relief printing technology. So how does a YDM UV flatbed printer achieve a 3D relief effect?

The core principle of a UV flatbed printer achieving a 3D relief effect is to layer UV-cured inks, combined with the instant curing characteristic of UV lamps, to form a three-dimensional texture with height differences on the surface of the printing medium. The specific workflow and principle can be divided into the following steps: Image Preprocessing and Height Layering

First, the image to be printed needs to be processed in professional RIP software, converting ordinary 2D images into 3D relief data with height information. The software will divide different height levels according to the brightness and color depth of the image. For example, areas in the image that need to be raised (such as logo edges and text) will be set as high-ink-volume layers, while flat background areas will be the base layer. The overall height of the relief can also be customized (usually between 0.1-2mm, some devices can achieve higher heights).

Layered Inkjet Stacking

UV flatbed printers use printheads to repeatedly spray ink onto the target area according to pre-processed height data:

For raised areas in embossing, the printhead first sprays a layer of UV ink onto that area. Then, UV curing lamps above or to the sides of the printhead immediately emit ultraviolet light, causing this ink layer to cure in a very short time (milliseconds).

The printhead then sprays ink again onto the cured ink layer, and this process is repeated several times, even dozens of times, until the preset height is reached.

For non-embossed areas, only 1-2 layers of ink are needed to achieve the basic color, thus creating the height difference between the flat and three-dimensional areas.

UV Ink Curing Characteristics

The UV-curing ink used in UV flatbed printers is the key material for achieving 3D embossing. This type of ink is solvent-free; its resin components undergo a rapid photopolymerization reaction under ultraviolet light, instantly transforming from a liquid to a solid state. The cured ink layer has high hardness, strong adhesion, and is not easily deformed. It is this instant curing characteristic that allows the ink layers to stack without collapsing, thus forming a stable three-dimensional structure.

In the later stages of high-precision 3D relief printing, after the stacking is completed, a surface touch-up or varnish coating will be applied: a layer of colored ink will be sprayed onto the raised relief texture surface to ensure uniform color of the pattern; or a varnish layer will be sprayed to enhance the gloss and wear and scratch resistance of the relief, while making the edges of the three-dimensional texture smoother.

Post time: Dec-05-2025