With the advancement of technology, negative pressure technology is applied to the UV printer industry,solve many UV ink supply problems.Today,let me introduce the difference between Positive Ink Supply System and Negative Ink Supply System.And when we choose UV printer,should we choose Negative or Positive.

What is Positive Ink Supply System?

The ink bag is directly installed at the carriage,the ink bag position is higher than printhead,directly utilize the height difference between ink bag and printhead,the weight of ink itself to achieve natural ink discharge.In the industry,most of small and medium size UV printer use this ink supply system.the system is sample,no need secondary ink cartridge,no need negative devices,lower cost.

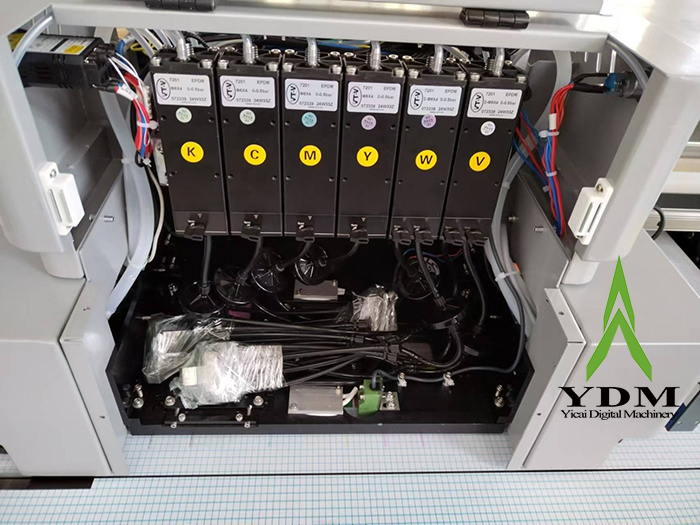

What is Negative Ink Supply System?

Control the pressure of secondary ink cartridge,it is below atmospheric pressure usually,that is negative,when no printing,the gravity of ink in secondary ink cartridge equals the atmospheric pressure,keep the ink suspended at the printhead;when printing,change the pressure in the secondary ink cartridge,to dis charge ink dynamically.

The advantage of Positive Ink Supply System

1.Price cheaper

2.If long time no use,still can maintain the printhead’s moist

The advantage of Negative Ink Supply System

1. Prevent ink leakage and ink interruption. The vacuum environment allows the ink to suspend and does not splash even at high speed, which is suitable for industrial-grade continuous printing;

2. Save maintenance. Automatic ink replenishment and color separation cleaning reduce 80% of manual intervention compared to positive pressure ink supply;

3. Compatible with complex inks, especially suitable for UV white ink containing particles, and high-density ink can also be stably delivered;

4. Finely control the size of ink drops to make the printed image clearer and the color reproduction higher;

5. Reduce the risk of nozzle clogging, reduce maintenance costs, and improve work efficiency;

6. Since the negative pressure ink supply system adopts a closed design, it can effectively prevent ink volatilization and pollution, ensuring long-term stable operation.

The disadvantage of Positive Ink Supply System

1.Easy to damage printhead, influence the printhead’s lifetime

2.Ink blockage, ink dripping and other failures are prone to occur during the printing process.

3.Print speed slow

The disadvantage of Negative Ink Supply System

Price High

Choose Negative Ink Supply System or Positive Ink Supply System

Negative Ink Supply System is suituable for print once and after long time to use again,Positive Ink Supply System is suitable for print everyday,high usage frequency customers,who needs high print speed.

Post time: Jun-13-2025