UV printer is a kind of digital printing machine,compared with traditional screen printing,UV printing doesn’t need make a template,can printing the design directly to acrylic,PVC sheet,wood,metal,glass,leather,etc.The new printing technology improved the production efficiency,simplified production steps.UV printing has fast printing speed, high color saturation restoration and simple operation advantages.However, when using UV printer, color deviation sometimes happens, leading to printing results not good enough. Do you know the reasons?

1. Picture – related issues

Before using a UV printer to print patterns, the printed images required must undergo processing. If errors occur during image processing, which lead to color degradation of the pattern, the resulting printing effect will deviate from the desired one. There are several specific reasons for this:

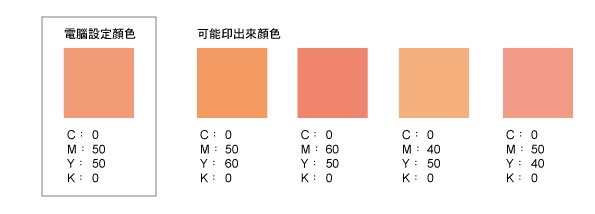

1) Computer monitors can display different visual color effects because of variations in brands, models, and color value settings.

2) The original design image color is in RGB format, rather than CMYK.

Therefore, it is advisable to test prints before the actual printing. Keep doing this until the expected effect is achieved, and then proceed with the official printing.

2. Ink – related problems

The quality of the ink plays a crucial role in the printing effect. If low – quality ink is used, it will not only fail to meet the printing requirements but may also mix with the ink in the cartridge, causing significant printing color deviations.

3. Environmental factors

When the working environment of the UV flatbed printer is overly humid, under such conditions, the UV ink may not dry thoroughly, thus affecting the printing effect. Additionally, when the working environment temperature of the UV printer is too low. May affect the fluidity of the ink.

UV printer Enviroment requirement:

Seperated, clean, low dust, well-ventilated environment

Woring Temperature:20°C-28°C

Relative humidity:40%-60%

4、ICC Color Profile

ICC color management is a comprehensive system developed by the International Color Association for the ICC standard format. The ICC curve serves is used to correct printing color deviations. Due to UV inks and the printing process, the printed ink often results in a deviation in the image. To solve this, an ICC curve is created, enabling good color reproduction for digital printing. Usually, the ICC curve is provided by the printer factory and integrated with the RIP software. Thus, prior to printing the graphic, when using RIP software, we need to select an appropriate ICC file.

YDM uv printer factory can adjust UV ink ICC curve for clients,if you buy YDM uv printer,you can enjoy lifetime free after sales service.when you meet these problems,just contact us,our engineers will help you to solve.

Post time: Jul-25-2025